|

Mould Base Standard : |

LKM Brand, Hasco, DME ect ; XUEJUN customed or As customers'Requirement |

|

Cavity/Core Material : |

S136, 2316,S316,ect ; XUEJUN customed or As customers'Requirement |

|

Cavity Qty : |

Multi-cavity(1-144cavity) ; |

|

Runner : |

Yudo/ Mastip/ HASCO/ DME/Or other hot runner As customers'Requirement |

|

Gate : |

pnuematic pin-point valve gate OR short tail OR long tail |

|

cooling system: |

spiral independent cooling system for each single core ,cavity and valve gate. |

|

Plastic Material for product: |

PET,PC,PP,ASetc; |

|

Mould Life Time : |

more than 2,000,000shots as per customers' requirement ; |

|

Lead Time : |

25-45 workdays based on the different products ; |

|

Package : |

Standard wooden case package or As per customers' requirement ; |

|

Price Terms : |

FOBNingboPort,China; |

|

Payment term: |

T/T, L/C at sight; |

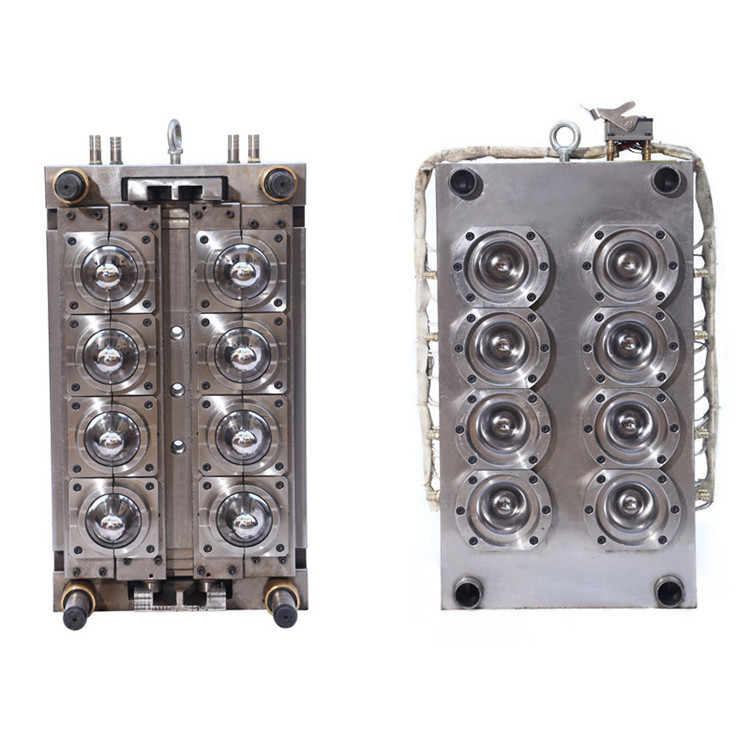

1.Mould structure

Advanced structure is designed to improve rate of finished

products;The each cavity is self locked independently with the core.The

off-center adjustment system make the perform thickness error less than0.05mm.Bottleneck is adopted International

Screw thread standard, No cutting of gate to reduce the labor intensity

2. Material of steel

Cavity and core use stainless steel 2316 with fine polishing,high

hardness to get mold's high precision and good quality. mechanical treatment

cavity and core to prolong service life,nitrogen treatment with neck screw.with

fitly operation,guarantee Long using life over 2 million shots of injection

cycle

3.About gate system

Pin-valve gate,pneumatic drive the nozzle pin simultaneous high

speed open and close action. which can effectively control the injection hole

open and close actions on each cavity. reliable seal function, smooth moving,

low thermal expansion rate ,long using life and also saves electric energy.

4.About hot runner

The hot runner system is designed and made by ourselves, it can

achieve ideal and prompt heating effect for preform production ,cavity with

lower injection pressure to reduce wear and tear of mould parts.we use the

double heating system,it has separate temperature control mode ,the heat bar

are used to heat the mould mainfold plate,small heaters supply the heating

temperature for cavity nozzle continuously.

5.Cooling system

Each parts including core ,cavity and valve gate has

independently cooling system.

6.special satisfied servive

Each mould undergoes strict mould test before delivery.we can

provide an experienced team for installation and test as per client's request

Standard inter-changeable mould components

High quality mould from good mould manufacture,we can design

different preform&bottle mould according to customer require.

Contact Us

TaiZhou HuangYan XueJun Mould Co.,Ltd

NO.10 Meihuajin Road, HuangYan, TaiZhou, ZheJiang, China

Tel:+86-576-84115538

Mobile:+86-15257615522

Fax:0086-0576-84115538

Email:xuejun@china-petmould.com